2020 Mountain Mango Outdoor Hemp Planting and Harvest

Cheyenne Wells, Colorado 2020

Cheyenne Mountain Seed Company had a great hemp growing season in eastern Colorado this year. Our partner’s farm is 150 miles straight east of Colorado Springs, just a few miles from the Kansas border. The weather was really good this fall with warm sunny days and cool nights which allowed us to harvest smokeable flower from October 5th through October 21. We waited until November 2 to harvest the biomass. What follows is a pictorial and video narration of the last 10 weeks of the season.

Timing the Harvest

60 Acres of Mountain Mango

Here is a view of the 120 acre irrigation pivot, half the circle was in corn and the other half was our Mountain Mango high CBD hemp. The circle was planted with a John Deere seed drill with disks modified for hemp seed.

Popcorn Buds – September 1st – Day 109

This picture was taken September 1st and we are just starting to see some flower. Since we planted on May 10th and most plants were germinated and popping out by May 15th it was day 109 of their growth, about 3 1/2 months. 74 days since the summer solstice.

Last year the plants were pummeled with hail 3 times toward the end of May. The whole crop was pretty much wiped out. There was no hail to mention this year so most of the seeds that germinated survived.

First Look at the Field – September 10th – Day 118

This is our first good look at the plants September 10th. Things were really getting into gear because they are going to grow another 2 to 3 feet in all directions before we start the harvest on October 5th.

Big Mama

The plants were really looking great, no pests or any disease. Some of the plants that got started quicker, got bigger and started flowering earlier like the one in this video.

This is Definitely a Good Start

Everyone is looking forward to a great harvest as long as the weather cooperates. A great deal of effort and expense went into hoeing and mowing the pigweed which can grow inches a day around here. You can see in this picture that its under control. Weed control represents one of the biggest costs in growing a crop under a pivot.

Harvesting for Smokeable Flower – October 5th Through October 21st

25 Days Later – October 4th – Day 143

It has been 25 days since the picture above was taken. The plants have really filled out and many of the buds have already developed into beautiful colas. It’s time to start harvesting our smokeable hemp flower.

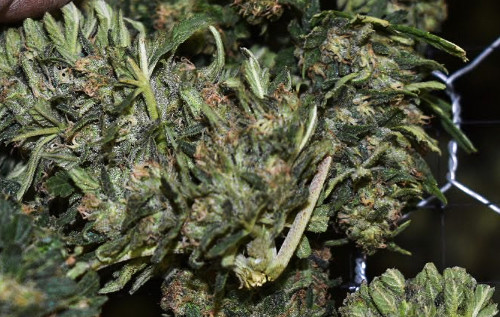

Big Colas

This is the size of Mountain Mango flower we want to harvest now. The plants are in various stages of development so we are only going to harvest the tops from the most mature plants.

Reed Says Just Pick the Fat Ones

This is the kind of top we are looking for. All the buds on this top have good size. Even the buds at the bottom of the stem, furthest in, are a nice size.

Let’s Get to Picking – October 5th – Day 144

Harvest for smokeable flower is starting. We are only taking the biggest tops we can find. The tops are put in 30 gallon totes and hauled back to the warehouse.

Leave These to Grow Some More

We have 60 acres to get through so we are leaving most of the plant.

First Tops from the Circle

These are some of the first tops harvested. Somebody has to manage quality control because there is still a lot of small stuff in the field and some of it is being cut and brought in for processing. Smokeable hemp is all about quality, every step of the process is important, not least being the size of each flower/bud that is cut.

Flower Processing Area

This is the area where we will buck and trim all the flower. We started out with one bucker and three one barrel trimmers, and quickly added 2 more buckers and 3 more trimmers. It’s best to have double the trimmers you are using because they need to be cleaned a lot and you don’t want to stop production.

On the Rack

This bud drying on the rack looks really great. It has nice size, lots of resin crystals and some color from the cold.

First Packaged Bud

By October 11th we had some flower dry enough to package, so we could get samples out to prospective buyers. These are one, two and three pound bags.

Morning Buds – October 8th – Day 147

The plants are getting bigger and better everyday. They are super fragrant in the morning after these cool nights.

Lookin’ Good – October 11th – Day 150

The structure of the flower is maturing into big, chunky buds.

Some Purple Showing – October 15th – Day 154

The night temperatures have been getting into the low 30’s for a while now, so we are starting to see color all over the field. Some of the plants have even turned purple like this one.

Big Green Island

This picture was taken about two miles away from the circle as the crow flies, the hemp field is about the only green ground in the whole area this late in the year.

She Was Pollinated

Some of the real early plants have seeds in them. They were pollinated from ditch weed growing in the area, miles away. Ditch weed males are dead and gone by the end of August so only real early maturing plants (there weren’t that many) had seed. We marked them so they wouldn’t be harvested for flower.

Sucking Deer – They Want Their CBD Too

It took me a while to figure out what was going on here because I’d occasionally see big buds that were all squeezed and malformed, but only randomly, here and there. The plants were usually out in the open and I was seeing deer tracks near it. Believe it or not the deer ‘suck’ on the big buds to get the juice out of them. They don’t eat any of the flower, just squeeze it with their powerful mouths, I assume to get the CBD and other oil out of the plant.

After a Hard Freeze – October 16th – Day 155

The morning of October 16th we had a hard freeze, our temperature gauges registered lows of around 26-27 degrees, I don’t know for how many hours. Really, it didn’t even nick them. Everything looked great and we are seeing bigger colas every day with more color in them.

Still Growing Bigger and Better – October 20th – Day 159

The flower keeps growing and maturing. It’s happening quickly now. They are really showing their stuff.

Oscar the Grouch

Sometimes you see a strange plant in the field. Out of 100,000 plants you will see some anomolies. This plant had really long leaves and huge colas.

Bringing in the Final Load – October 21st – Day 160

Last load of smokeable flower from the circle, which was 7 miles from the processing warehouse.

The End is Near – October 21st – Day 160

We are expecting to have a heavy freeze tonight which may wipe out the whole 60 acres. I am marking off a small area to save when the combine comes through.

The Smokeable Harvest is Over – Waiting to Harvest Biomass

The Next Morning – October 22nd – Day 161

They got nicked a little last night.

All The Water Leaves Wilted

Our temperature gauges only registered a low of 27 degrees, the same temperature as on October 16th, but the wind blew for so long and so hard (35-40 mph) that the wind chill got them. The bud is still fine, just the big leaves got whacked.

Bud is Healthy – October 23rd – Day 162

The flower still looks good 2 days after the freeze. A lot of the fan leaves are still good, hemp is incredibly tough once it has set heavy flower. We could definitely still pick this stuff but the harvest is over.

We Had a Real Hard Freeze

October 25th & 26th – Day 164 & 165

The first day we had high winds and cold, then it snowed and got down to 10 degrees. The plants were protected by the snow that covered them.

They’re Not Pristine

The plants are in amazingly good shape after two nights pushing single digit temperatures. The snow insulation helped, but don’t think they just die when the temperatures get below freezing.

Snow Blanket

The temperature on this gauge shows a low of 17.3 degrees even though the reported lows were around 10 degrees. It took a while to find this gauge because it was under 3 inches of snow.

After the Snow Melted

October 29th – Day 168

The outside of the buds have turned golden, but they are still alive inside. We could still be out harvesting tops, there’s at least 10,000 pounds left out here.

Crystals in the Sun

The trichomes are intact, this flower still looks really great.

Plants are Definitely Alive

October 29th – Day 168

Even after all the freezing, the plants are still alive. These are some bottom branches that were covered in snow 3 days before. The outside of the buds have dried out but inside they are still green and alive. Cutting a branch shows green bark.

Biomass Harvest – November 2nd through November 4th

Biomass Harvest

November 2nd – Day 172

The weather wouldn’t cooperate until November 2nd to start the biomass harvest. Wind blows hard in eastern Colorado and if it moves the windrows down the field they will shed a lot of their trichomes as they roll in the wind. The plants were cut with machetes and laid in windrows to dry before the combine picked them up. It dried quickly once it was on the ground.

Quick Work

This team ripped through 60 acres in 20 hours. They carry portable grinders to keep those machetes real sharp.

Three Wacks and It’s Down

This is a big stump. The wind blows so hard out here, and so often, that the plants really need some wood to stand up to it. Of course hemp plants adapt easily since they are some of the toughest plants on earth.

Combine This Fine Bud

Here comes the combine and its all over.

Load the Trailer

The combine doesn’t hold that much, so it has to unload into the trailer often.

Unload the Trailer

It’s easier just to back the trailer into the building.

Load the Conveyer

The trailer has a nice conveyer so its easy to load the Supersack conveyor.

Put it in the Supersacks

We load about 500 pounds of biomass in each sack.

Stack the Sacks

We ended up with about 80,000 pounds of biomass. Most of the leaves were off the plants when the combine came through so it was pretty much pure flower.

Little Garden

Out of 60 acres, this is all that’s left. That didn’t take long at all.

It’s Really Over

November 4th – Day 174

Sunset on the hemp field, combine and tractor trailer. The Mountain Mango hemp plants grew for 174 days, almost 6 months, in eastern Colorado. Quite an accomplishment in this harsh but fertile environment.

The Final Tally

The Final Tally

Here is all the planting, hoeing, mowing, driving, sweating, watering, cutting, cussing, trimming, racking, drying and packaging. 80,000 pounds of biomass and 7,500 pounds of smokeable flower.

Planting and Cultivating Costs

Our cost per acre was about $3,000. Almost 90% of the expense was for hoeing labor and seed. We can calculate the cost for smokeable hemp flower at $ 19.56 per pound and hemp biomass at $.46 per pound. Based on sales smokeable flower is calculated at 80% of the cost and biomass 20%.

Harvesting Costs

Most of the harvesting costs were for the smokeable hemp. We spent around $30,000 on the biomass harvest, so over $120,000 was spent on the flower. That works out to $16.40 per pound to harvest and package the smokeable flower. Biomass harvest was around $.38 per pound.

Final Yield and Gross Profit

There will be other expenses like sales commission and freight to actually sell all this product, but this is our projected gross profit. Smokeable flower will generate at least 80% of the sales dollars. Gross profit should be around 70% of total sales, not bad at all.

The costs for a pound of packaged smokeable hemp flower is calculated at $35.96 and a pound of hemp biomass at $.84 a pound. If the average price per pound is $125 that’s a gross profit of 72%. If the price of a pound of biomass is $3 that’s a gross profit of 72% also. Of course there are a lot more sales dollars in smokeable hemp flower so it’s way more profitable to the bottom line.

| Planting and Cultivating Expenses | |

|---|---|

| Basic Costs per Acre | |

| Field Rent | 150 |

| Fertilizer | 27 |

| Water | 85 |

| Planting and Cultivation | 45 |

| 3,000 seeds per acre @$.50 each | 1,500 |

| Hoeing Labor | 1,200 |

| Mowing Equipment and Labor | 50 |

| Total Per Acre | 3,057 |

| Total For 60 Acres | $183,420 |

| Harvesting Costs | |

|---|---|

| Used Buckers & Trimmers | 47,000 |

| Field Harvest, bucking, trimming, racking expense | 70,000 |

| Combine and trucks | 12,000 |

| Machete windrow team | 15,000 |

| Supersacks, mylar bags and sealers, bins and totes | 9,000 |

| Total Harvesting Costs | $153,000 |

| Harvest Yield and Projected Gross Profit | |

|---|---|

| 3,500 Pounds Grade A Machine Trimmed Flower @$100 per pound | 350,000 |

| 4,000 Pounds Grade A+ Machine Trimmed Flower @$150 per pound | 600,000 |

| 80,000 pounds Biomass @$3 per pound | 240,000 |

| Total Revenue | 1,190,000 |

| Total Expenses | 336,000 |

| Projected Gross Profit | 854,000 |

How we Process Smokeable Hemp

Cutting in the Field

We are only cutting the top colas. The plants in the foreground had one to three tops taken from each one. Some of the plants are 8 to 10 feet wide so there are a lot of nice tops to choose from.

Bringing in the Sheaves

All the tops are put into totes and loaded in a trailer and brought back to the warehouse.

Unload the Flower

Take all the totes out of the trailer.

Weigh It

After unloading, each tote is weighed so we know the gross pounds brought in from the field each day.

Bucking

The bucker strips the bud off of the stems. These machines take some skill to operate so the buds aren’t broken up and turned into larf.

Wet Trimming

It’s important to run the buds through the trimmer before they start to wilt. These machines determine the look of the final product, which is a huge quality issue. Skill is required to operate these machines so they turn out quality trimmed bud.

Rack It

After wet trimming, the tote is weighed so we know the processed wet weight, then flower is spread out on the drying racks.

Let it Dry

The bud will stay on the racks for several days depending on ambient temperature and humidity. We don’t put fans directly on them normally, just open the overhead doors and let the air flow through the whole building. If its rainy or real humid then you have to change tactics.

Bin It

After the flower has dried to a certain point, we put it in the bins. This will start the curing process and get the moisture level consistent in the whole bin. We put the lid on, let it sweat, then take the lid off and flip the bin. Let it dry, flip it, cover it, etc. It takes some skill and experience to get the bud ready to package.

Pack It

When the flower is ready, we pack it in these mylar bags which hold 5 pounds. The moisture content of the bud when packaged is around 10%.